“Monitoring of movements in x, y and z ensures safety”

Monitoring solution

The purpose of monitoring is safety. Safety in knowing that movement on a building or on a slope will be detected in time to send out a warning and in time to take the necessary precautions to avoid damage on equipment and on people. LIFA also sets up and runs a SHM system (Structural Health Monitoring) where buildings etc. are continuously monitored to follow change in conditions, movements and in structure.

LIFA uses, amongst other things, the following equipment:

- Traditional land surveying instruments

- Total Station/RTS (Robotic Total Station)

- GNSS sensor (GPS)

- Leveling instrument

- Geotechnical sensors

- Inclinometer/Tilt sensor

- Extensometer

- Hydrostatic sensor

- Load cell

- Weather sensor

- Weather station

- Water level sensor

The following list is a selection of monitoring tasks performed by LIFA:

- Rail road tracks

- Bridges

- Secant piles

- Landslide

Download flyer

Rail road tracks

Traditionally rail road tracks are monitored in intervals of months or years depending on how high a risk area they are in. They are monitored with traditional land surveying instruments such as a leveling instrument. But sometimes construction work around the rail road tracks might increase the risk damages and a more constant monitoring of the tracks is needed.

An example: An underpass is being built through a railway embankment. The railway company is worried the tracks might move while the work on the underpass is going on. A monitoring system is set up. The system is based on traditional land surveying using total stations. The total stations are linked to a power supply and a communication unit. This unit sends observations from the total station to a server at LIFA. It is possible to follow the monitoring real-time on the internet.

The monitoring system has a build-in threshold value and when this value is hit an alarm goes off. If the alarm goes off all trains on this stretch are stopped. Stopping the trains and the people working on the underpass before anything serious happen, ensures safety and money saved on damaged equipment.

Bridges

When it comes to bridges LIFA has great experience in monitoring different kinds of movements. But we also have experience in setting up a system for monitoring the weather and the water level. We know how to combine older analog systems with new digital ones, and how to get a new system to work together with an existing one.

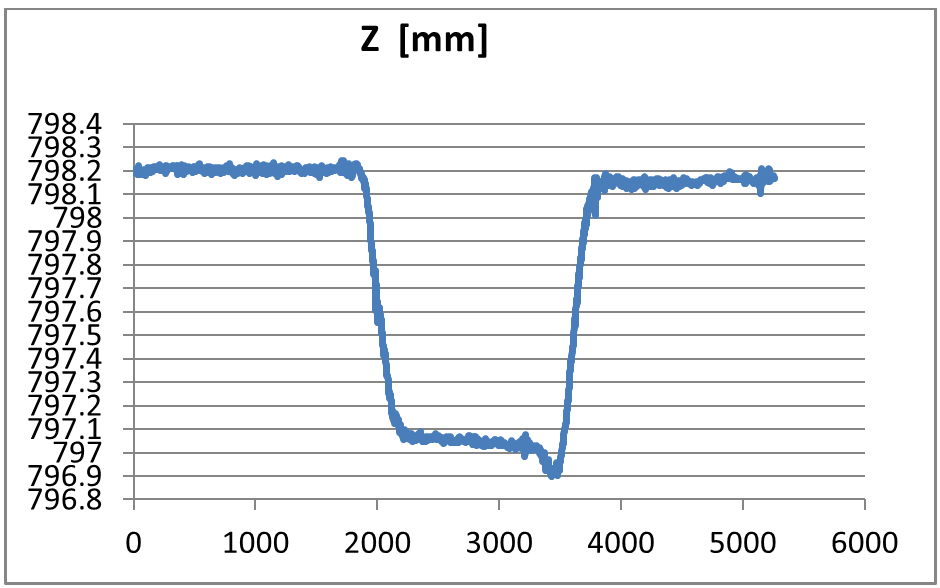

An example: LIFA is contacted by a company who wishes to work together on precision monitoring of a bridge. The purpose of the job is to monitor the movements of the bridge when a truck passes. The criteria for the job are high precision and high frequency in measuring. To meet these criteria a laser tracker is used. At a distance of 10 m and with a frequency of 100 Hz each target are measured when the truck is in the following positions on the bridge:

- Truck moving across the bridge in one side

- Truck moving across the bridge in the other side

- Truck parked on the bridge in one side

- Truck parked on the bridge in the other side

All datasets are collected in csv-files with a timestamp for each observation. This made it easy for our work partner to use the data in combination with the data they were collecting simultaneously.

The graph illustrates how much the bridge moved when the truck was on it.

Secant piles

When excavating for a building or something else it is important that the walls of the excavation are strong and they hold what is expected of them. This often results in using an extra amount of concrete just to be on the safe side. By monitoring the secant piles as a part of the building processes it is possible to use less concrete and reduce expenses on building materials. This method is called NATM (New Austrian Tunneling Method).

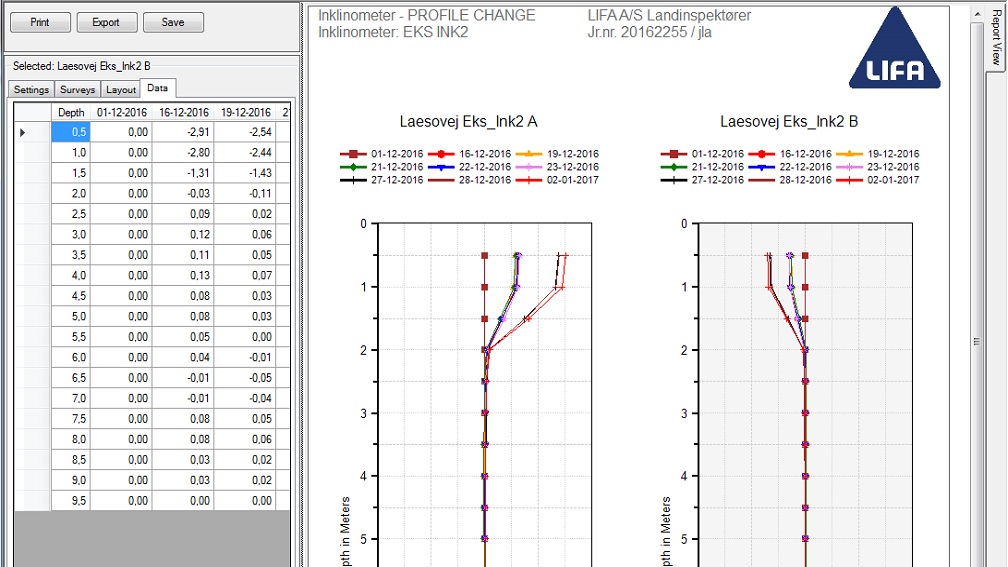

An example: As a part of a large urban development project an excavation has been done to build an underground parking area. Secant piles are casted to hold the walls of the excavation. LIFA is contacted to assist in monitoring the secant piles to make sure they are strong enough or locate where reinforcements are necessary.

To monitor the secant piles several 10 m long inclinometer pipes are placed in the secant piles different places around the excavation. Each week all of the pipes are measured using an inclinometer and the movement is registered. If the tolerances are not kept reinforcements of the secant piles will be done.

Landslide

Monitoring surface movement is done with a wide range of different systems depending on what kind of information you wish to collect.

An example: During a clearing of a slope close to the sea a landslide happens and exposes an important pipeline. The owner of the pipeline is worried and wants an on-going monitoring that the pipeline is safe before work on the slope continues.

In the beginning of the monitoring process a series of fixed points are established and once every month measured using a GPS. The observations are compared to the initial measurement. The movements are followed through several months. Each time it is evident that some of the points are moving towards the sea.

The question now is how deep these movements are. To find this answer a series of inclinometer pipes are placed at selected points within the work area on the slope. They are measured once every week a couple of months before the work at the site continue.

During the building phase the inclinometer pipes are monitored once every day. From the result of the measurements it is evident that the movements only exists in the first 2 meters from the surface and mostly on the inclinometer pipes closest to the sea.

The on-going monitoring keeps an eye on the surface around the pipeline and work stops if movements close to it are detected.